VERTICAL BLIND MACHINES

VB SUPRA WORKS WITH NEW THICKER & TEXTURED FABRICS

The NEW fully Australian designed and manufactured WM-VB1 is now being re-named to the VB Supra

We want to avoid confusion with the old VB1 model.

Williams Manufacturing has so radically improved the VB Supra design to make the new machine so much accurate and consistent, as well as being more ergonomic and intuitive to operate.

Our VB Supra Vertical Blind Cut Punch and Crease machine is a masterpiece of Australian design and engineering.

The VB Supra Vertical Blind Machine has all the advantages for Australian Vertical Blind manufacturers

- The VB Supra now includes six new programmed fabric selection ranges based on fabric thickness and textures.

- The six selections will automatically preset the calibration for your fabrics.

- The operator will be able to select these different fabric ranges knowing the machine settings are optimal for each different range.

- The ranges will be identified with a name that will be easy for your operator to relate to – for example, we can set up the VB Supra up with your most used Fabric Names.

- Raytech will work through these requirements and identifiers with you, and arrange for your fabrics to be tested if it’s needed.

We're supporting Australian manufacturers with parts, service and repairs for all our vertical blind machines

Williams Machinery has over 17 years experience on the previous model machines, and has completely designed the SUPRA. All Supra parts are held locally in Australia.

VB SUPRA FEATURES

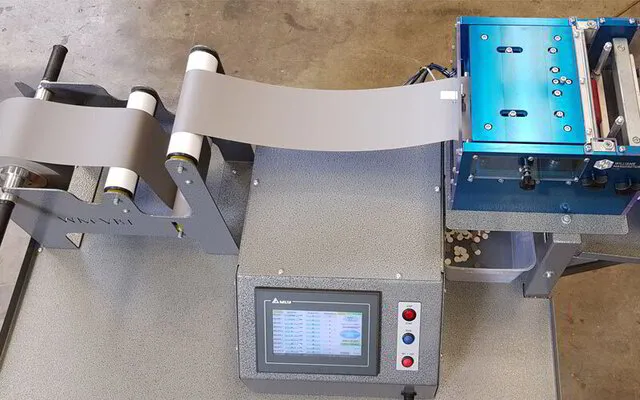

- New improved bigger and easier to navigate TOUCH SCREEN

- 6 calibration ranges to be accurate first time with every fabric type

- New improved ergonomics (no foot stools)

- Passive in feed tension control system

- New improved PLC with more intuitive easier calibration

- Stacks automatically in a perfectly neat pile

- Fast, accurate and can do up to ten blinds in one operation

- Counts down the louvres so you see what blind is being made

- Faster on average 16 – 20 louvers/minute

- Gives a fabric-required and fabric-used read out

- Places marker tabs between blinds – easy take off

- Fabric-out sensors – auto stop until reloaded

- Compact so it can fit in any workshop

- Delivery chute included to keep louvres off the floor

- Receptacle to catch all the punched out holes

- Much easier to clear and tape or fabric jams

- Compact and on castor wheels

- Comes in a crate, set up and ready to run without an installation

- OPTION: New silent compressor – way bigger tank and quieter operation

- COMING SOON: Blind data upload via LAN from office or via USB

Improved Ergonomics

Our previous model has the machine head up high on a post requiring operators to hop on a stool to load fabric and feed into the machine head. If machine operators weren’t very tall they had difficulty.

The machine head and roll holder is now at an ergonomic height – not mounted up on a post

Bigger Touch Screen, Easier Operation

- Much bigger touch screen for easier operator interface.

- Louvres remaining count down - see at a glance the quantity left to make.

- See the whole 10 blinds on screen – really easy to edit.

- Easier calibration of machine with prompts on screen to help with the process.

- So easy to then make one extra louvre for any blind

- Clearer and more intuitive to operate and with helpful pointers on screen.

Fabric In Feed

On the left side of the machine the infeed has a great system of passive rollers for dealing with the various tension of the roll – this eliminates the drag on fabric entering the machine head it means that slightly inconsistent lengths due to this is totally eliminated – a really fantastic new feature.

The infeed has a bearing mounted roll holder to slip through the fabric roll and then it is simply placed on the machine – so easy

Louvre Outfeed

The chute comes in 2 parts so 2100mm louvre is off the floor if you use the full chute. The chute comes apart in the middle to a delivery height at 900 mm, a standard bench height

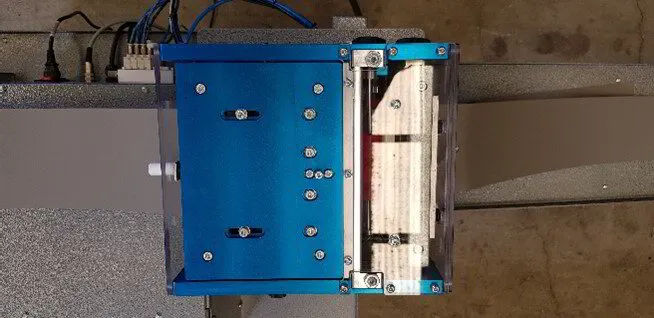

Waste Bin

Waste fabric from punched out holes typically end up on the floor all around a vertical blind machine. No more sweeping up! A collection shaft delivers them straight into a waste plastic bin.

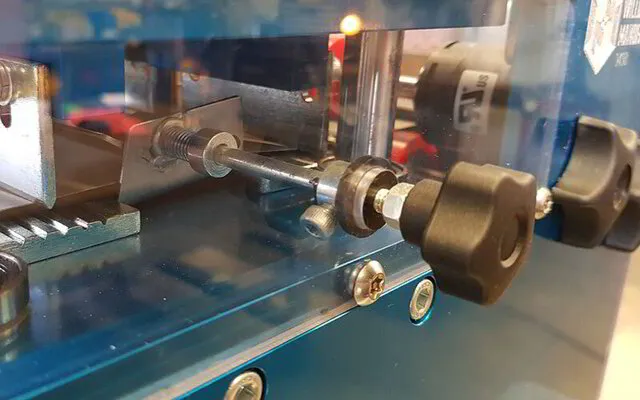

Easy access to Drive Roller

Fast easy slide out of the drive roller and the counting roller so it is easy to remove masking tape or to clean rollers as required.

There is now adjustment of tension on the counting roller, making it easy to keep the machine accurate. With no adjustment on the old VB1 inaccuracy became an increasing problem

With this new design many service issues can be performed by clients or better able to keep the machine accurate with help available over the phone or via a smart device.

Rapid set up

The VB Supra can come to you in a crate and it is on its castor wheels so after it is lifted out on the floor it is simply a case of bolting the chute on and connecting the power and air. You can be running in only a few minutes. We’ll be happy to guide you through the screens and initial operation. An operator manual will be included.

For overseas clients we can also flat pack the VB1 Cabinet. This would lower the shipping costs.